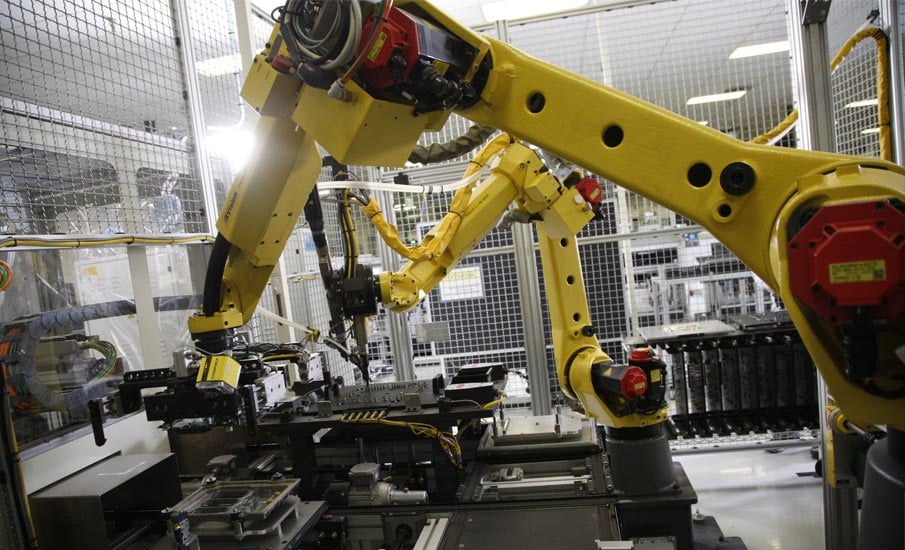

John Deere Electronics continually works to improve the efficiency of its processes. Our continuous improvement activities are the keystone of our manufacturing quality program. Daily, continuous improvement teams work with the operators on the floor to drive increases in our productivity, safety, quality, and delivery metrics.

Eliminating Waste, Increasing Profitability

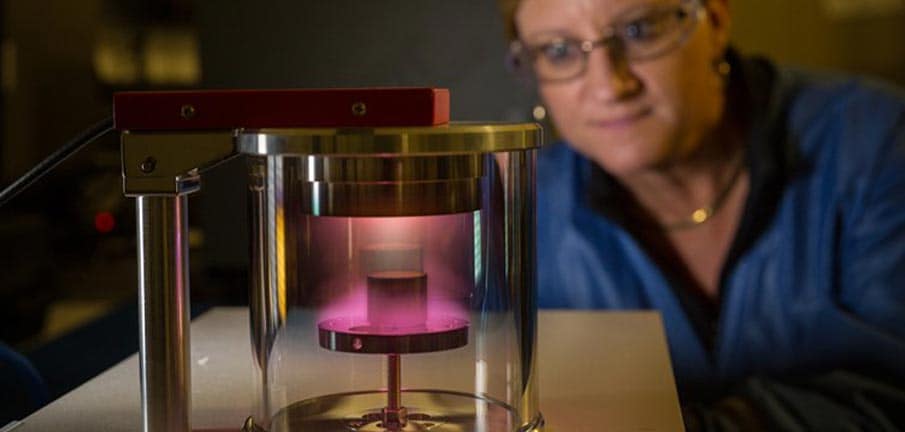

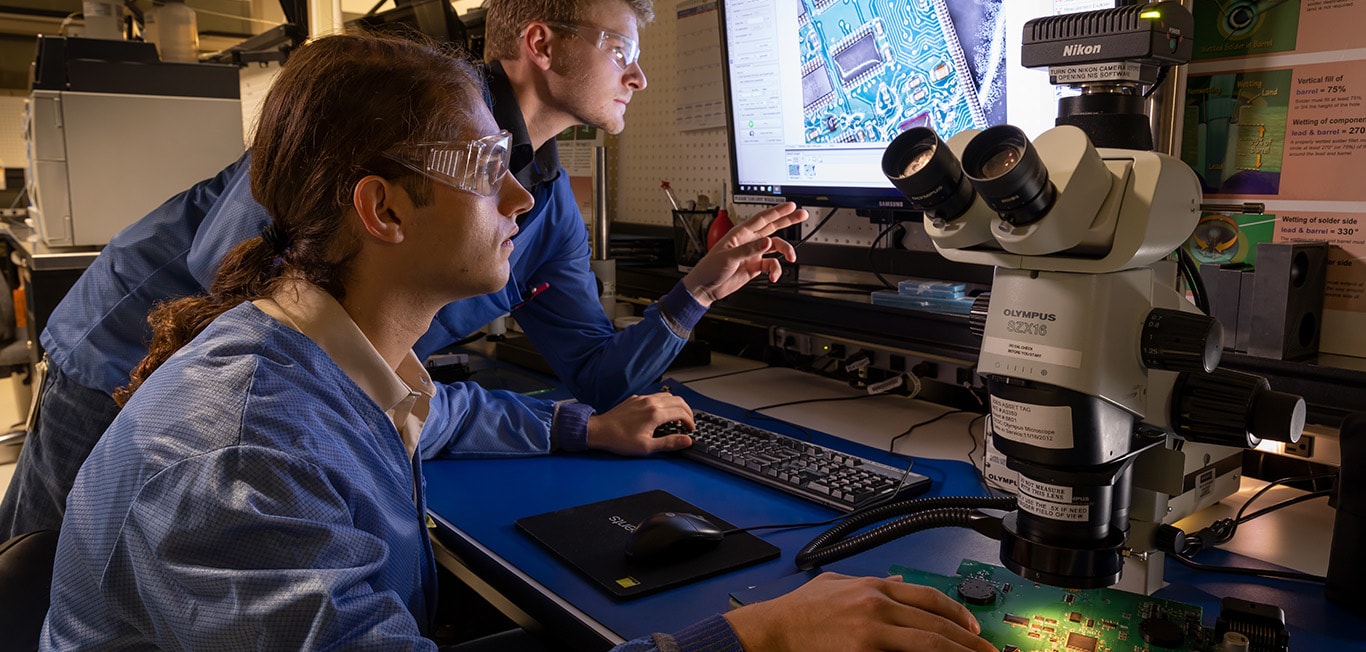

John Deere Electronics strives for further efficiency and process improvements throughout the company by embracing a "lean manufacturing" philosophy that promotes better production controls to eliminate waste and increase profitability. Our manufacturing organization is a very metric-driven organization. We have manufacturing floor systems designed to monitor and track quality, so early detection of potential quality issues is an important part of the process. We have systems in place to monitor product yields and trends on the manufacturing equipment, tying it all together so that we know we are building a quality product every day based on the product monitoring metrics that we've developed.