As if up to 7,200 bushels per hour weren't enough.

It started with sheer brawn, when we gave the legendary X9 Combine the muscle to deliver up to 7,200 bushels (253,721 liters) per hour in high-yielding corn1. A combine that raised harvesting capacity by an average of 45% — while using 20% less fuel2. We gave it vision to see ahead and automatically adjust speed to crop volume. And we made combine settings as easy as one, two, three.

What else could we do? Well, turns out a lot. We added more harvesting smarts. We gave it hands-free automatic turning. We made it easy to share real-time grain weights with your entire harvest team and we automated the unloading process. We even found time to add a better instructional seat. All the power. All the productivity. All the comfort. Now that's taking things to the X level.

Automation

Predictive Ground Speed Automation

Increase productivity by up to 20%* with Predictive Ground Speed Automation1, included in the optional Ultimate Technology Package. Using two forward, cab-mounted stereo cameras, the X9 constantly measures crop height and volume — while pre-harvest satellite field images generate a predictive field map. The combine takes this data and automatically adjusts ground speed BEFORE entering changing crop areas. Feel confident to maintain peak feed rates all day long, even in inconsistent crop conditions.

Harvest Settings Automation

Harvest Settings Automation – included in the Premium and Ultimate Technology Packages – makes it easier than ever to set the specific outcomes you expect. Using your G5Plus Display, simply set acceptable limits for grain loss, foreign material, and broken grain. Once set, the combine automatically adjusts itself to deliver the performance you want. No more manually adjusting rotor speed, fan speed, and concave, chaffer, and sieve clearances. The combine does it for you according to outcomes you’ve already prescribed. That gets you into crops faster and reduces the things you have to constantly monitor.

AutoTrac™ Turn Automation with Header Raise/Lower

COMING SOON

More and more operators are discovering the hands-free confidence AutoTrac Turn Automation (ATTA) gives them during in-crop turns. But they still had to remember to raise and lower the header. Not anymore. Coming soon we're adding the capability to automatically raise and lower your header. Always at the right time. Always at the right place. That's one less task to worry about, so you can concentrate on more important things. Check back later or ask your John Deere dealer for more details.

Capacity

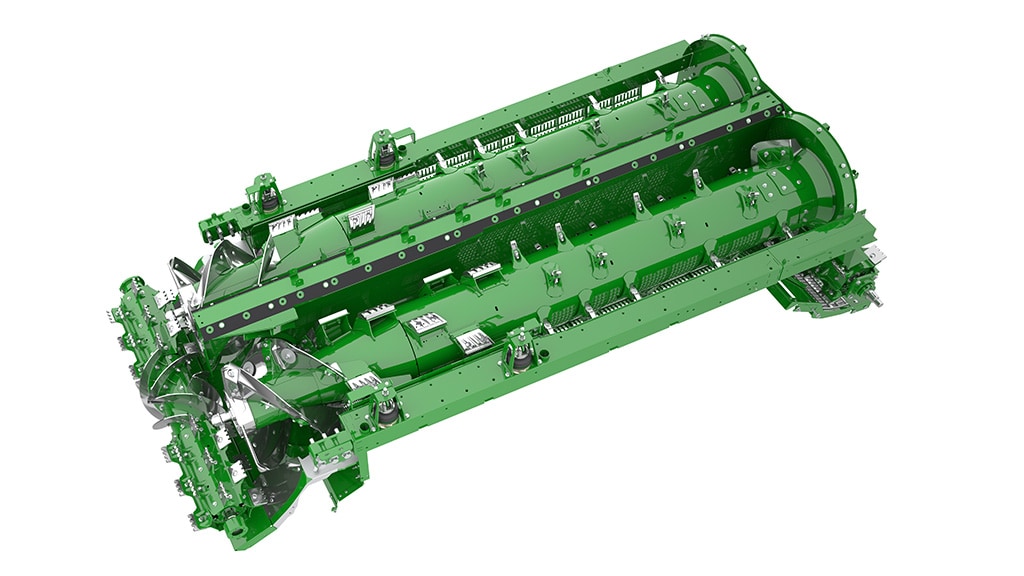

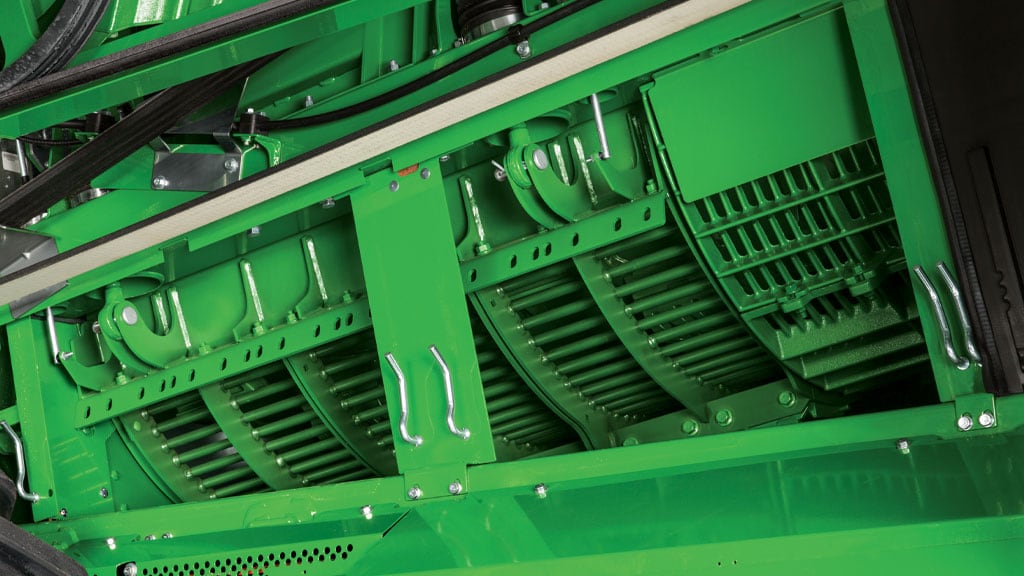

Dual separator

Two 24-inch (60.96-centimeters) rotors with an increased threshing area of 45% and separating area of 80%3 for better threshing and separating in high-volume crops.

Cleaning shoe

New shoe offers 36%2 more cleaning area to effectively put clean grain in the tank in the toughest harvesting conditions.

Bigger on the inside

Even with 45% more threshing area3, and 80% more separating area3, the outside dimensions are about the same as the S7 900, for tight turns and narrow transport.

Efficiency

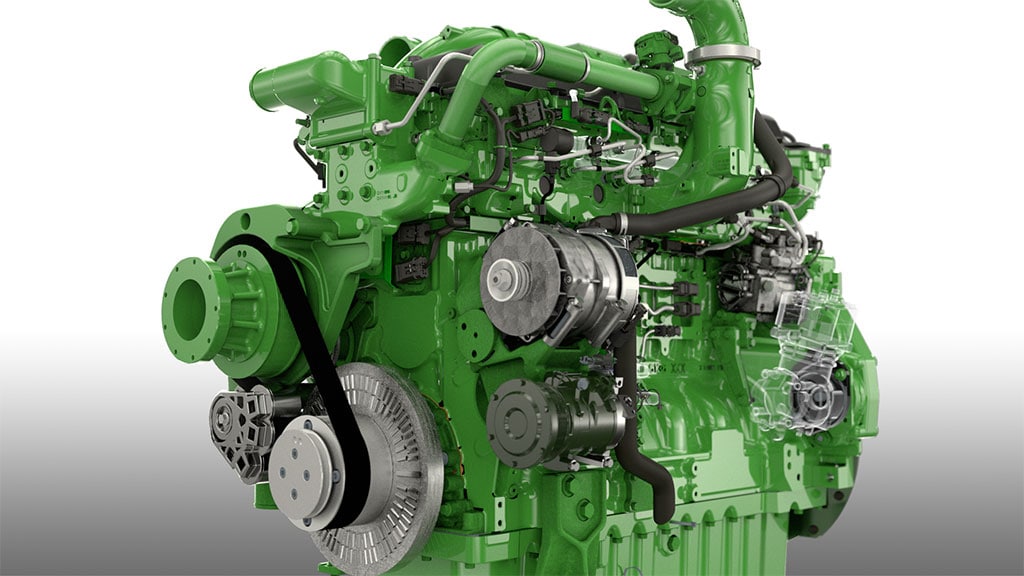

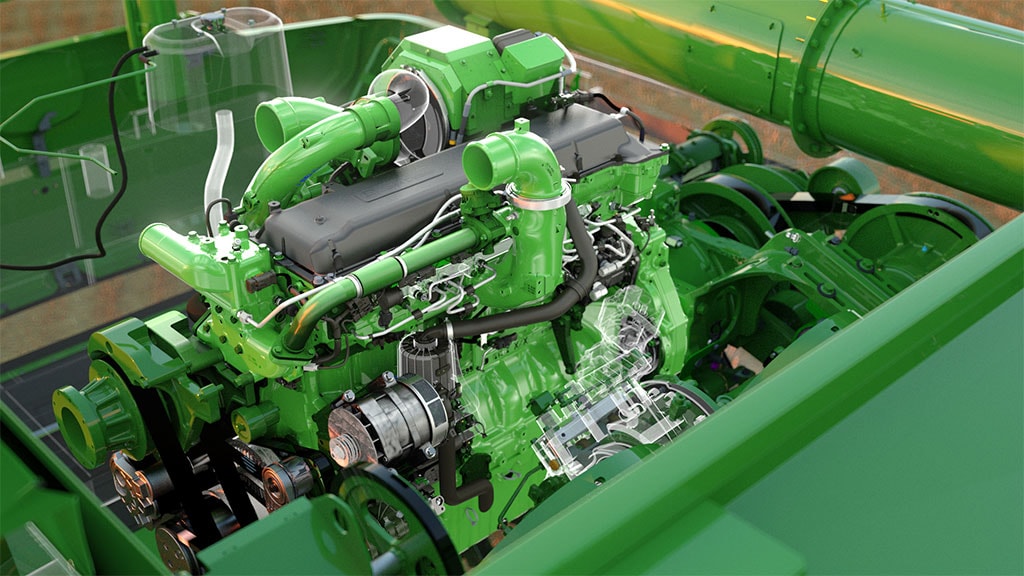

A more efficient engine

A John Deere JD14 13.6L engine delivers up to a 45% increase in harvesting capacity, while only needing 11% more horsepower than an S7 9003.

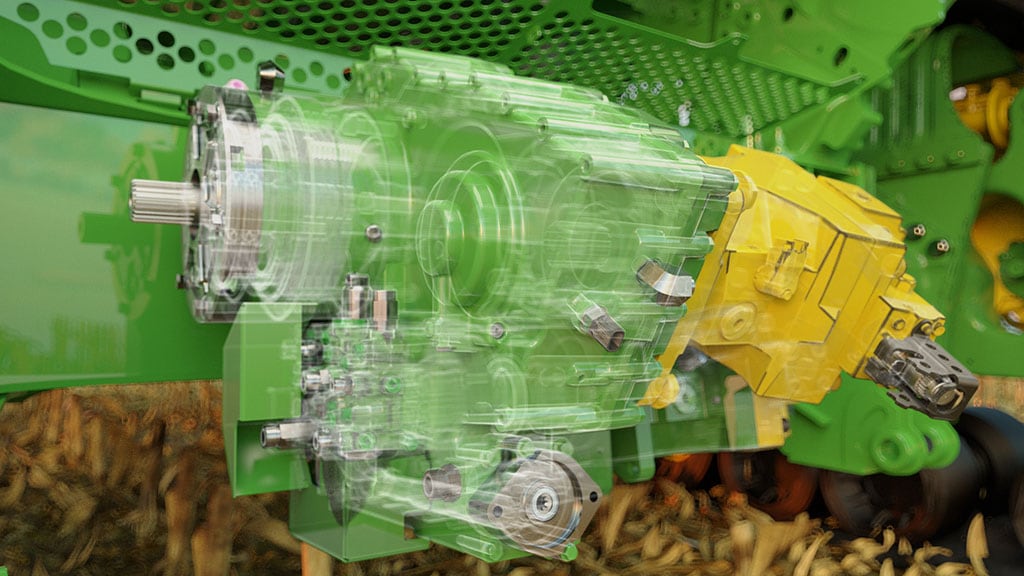

Seamless speed control

30%2 more torque to handle larger loads with a smooth power increase with the new ProDrive™ XL transmission.

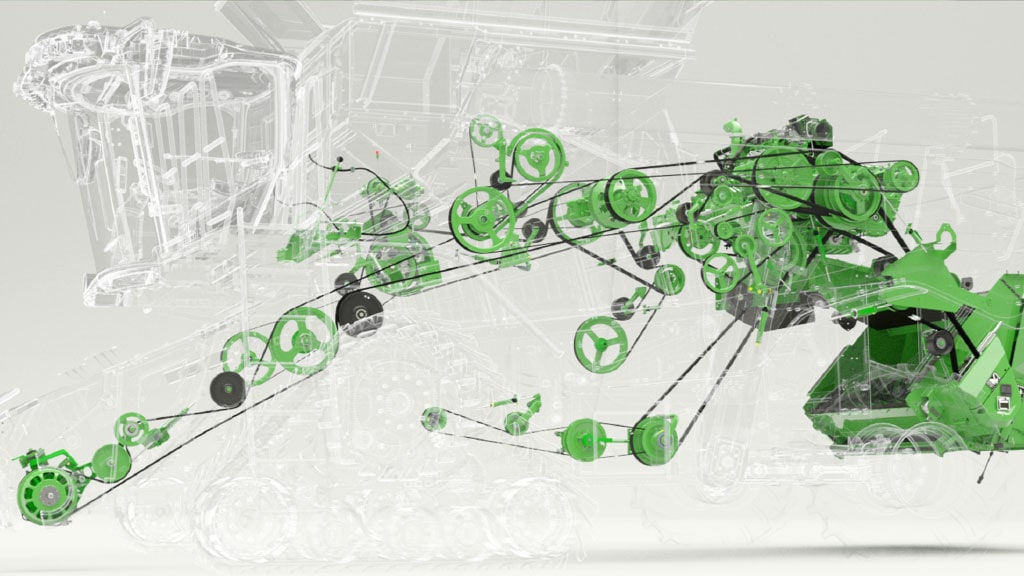

Belt-drive system

Our simplified belt-drive system uses larger pulleys and longer belts to improve the handoff of power and belt wear-life2.

20% less fuel2

It's not just the engine that delivers lower fuel costs, it's every aspect of the design. The belts, transmission, residue system, rotors, and lower RPM all play a role in saving you money on fuel.

Improved residue management

New system spreads up to 50-feet (15.24-meters) wide; the double-decker design provides better air flow for even distribution with less power consumption2.

Calculate Potential Savings

See what you can save each harvest season with the Harvesting Performance Calculator. Enter your operation's inputs and operating variables to calculate the estimated savings by switching to John Deere harvesting equipment.

Versatility

Integrated intelligence

From the Integrated StarFire™ Receiver to JDLink™ Connectivity, the X9 Combine comes ready to make your harvest easier.

Get More in Rice

Gain resistance to the abrasiveness of rice, along with up to 65%4 more capacity while using 20% less fuel5 with the tough, wear-resistant X9 Rice combine package.

Choose from wheels or tracks

Tracks deliver improved floatation and allow for transport speeds up to 25 miles per hour (40.23 kilometers per hour).

Easy-change concaves

Lighter concaves make switching crops even easier.

Reduced plugging

The modulated feederhouse reverse allows the feederhouse to reverse under full engine RPM to reduce the chance of plugging in heavy crop.

In-cab control

With the G5Plus CommandCenterTM Display, you get in-cab control of the power folding unloading auger and adjustable spout for easier unloading and residue adjustments.

Headers and Platforms

X9 Combines are engineered to create a perfect balance between front-end equipment and machine power, so together they deliver stable, consistent performance with every pass, even in tough conditions.

Corn Heads

Drapers

Belt Pickup

More power, without more fuel use

X9 Combines have a new John Deere JD14 13.6-liter engine, which delivers a 14% increase in power and an 11% increase in torque over the 13.5-liter engine. A high-pressure common rail system more efficiently injects fuel into the engine for additional fuel savings.

Maintenance & Reliability

Our combines are supported by one of the most responsive dealer networks in the business.

John Deere Connected Support™

Keep running. That's job one of John Deere Connected Support. You can reduce downtime with connected tools that remotely monitor and proactively service your combine.

John Deere Protect Plans

Annual Expert Inspections and regular scheduled maintenance, coupled with PowerGard™ extended warranty will help ensure "like new" performance and uptime of your combine and reduce unexpected expenses for up to 36 months.

Inspections

Keep your combine in tip-top condition with comprehensive inspections. Our highly trained technicians will replace worn parts and tune up other key areas.

You Also May Be Interested In

*Claimed based on same model running in the same crop over the same amount of acreage, one with Predictive Ground Speed Automation on and one with it off.

1Based on internal testing, performance claims based on field and crop conditions at the time of testing; individual results may vary.

2Internal comparison between X9 1100 and S790 Combines, based on field conditions, per-unit harvested. Pre-production model shown.

3Internal comparison between X9 1100 and S790 Combines, based on field conditions, per unit harvested.

4Internal comparison between X9 1000 and S790 Combines

5Internal comparison between X9 1000 and X790; results vary depending on field conditions.