Agriculture, Farm Operation September 01, 2023

Sunny Days Ahead

.

Drought years forced farm to change course.

When one door closes another one opens, right? For Tom Smude's farm outside Pierz, Minn., it was more like when one thing dries up, several more spring forth.

He and his wife, Jenni, never could have imagined how many enterprises they would have in their portfolio now, almost 15 years after brainstorming a more drought-tolerant feed crop for their beef cattle.

Tom says, looking back, it has been a dream come true, but it is not the route he envisioned.

They moved onto their farmstead in 1998 with cattle and farmed a few hundred acres while also both working full-time off the farm.

"My grandfather bought three cows for me at the sale barn when I was 18 for $760 a piece. I remember thinking with those first three calves, 'how do I get these to a plate at a restaurant?'" he says as passionately as if it was just the other day. "It took 30 years, but we are here now."

Direct-sale beef is one of the eight enterprises Smudes manage today. They have sized up their Angus herd steadily, adding an on-farm feedlot in 2005. This enabled them to start selling direct to consumers and building relationships with area chefs.

But then the rain dried up.

They experienced devastating drought two years in a row, just after getting into those new and exciting markets. Thinking they could manage their risk on feed crops by adding more acres, the farm they were set to buy fell through.

Tom and Jenni—though cautious and conservative in their business operations—are not ones to let three strikes knock them out. Instead, they changed their plans and kept pushing forward.

"I was in a sales training years ago where the instructor said: if you remember one thing from me it is that 'persistence wears down resistance.' That always stuck with me," Tom says, reflecting on how many hurdles they have overcome to get where they are today.

Above. Tom Smude, farmer and entrepreneur from Pierz, Minn. Out of the need to find an alternative feed crop for their cattle, Tom and his wife, Jenni, have built a mid-sized company in their small town with eight different ventures including direct-sale beef and sunflower oil products. The oil has become the star of the show. They now sell it as traditional and flavored cooking oil, and also sell surplus protein and oil as bulk ingredients to other human and pet food manufacturers.

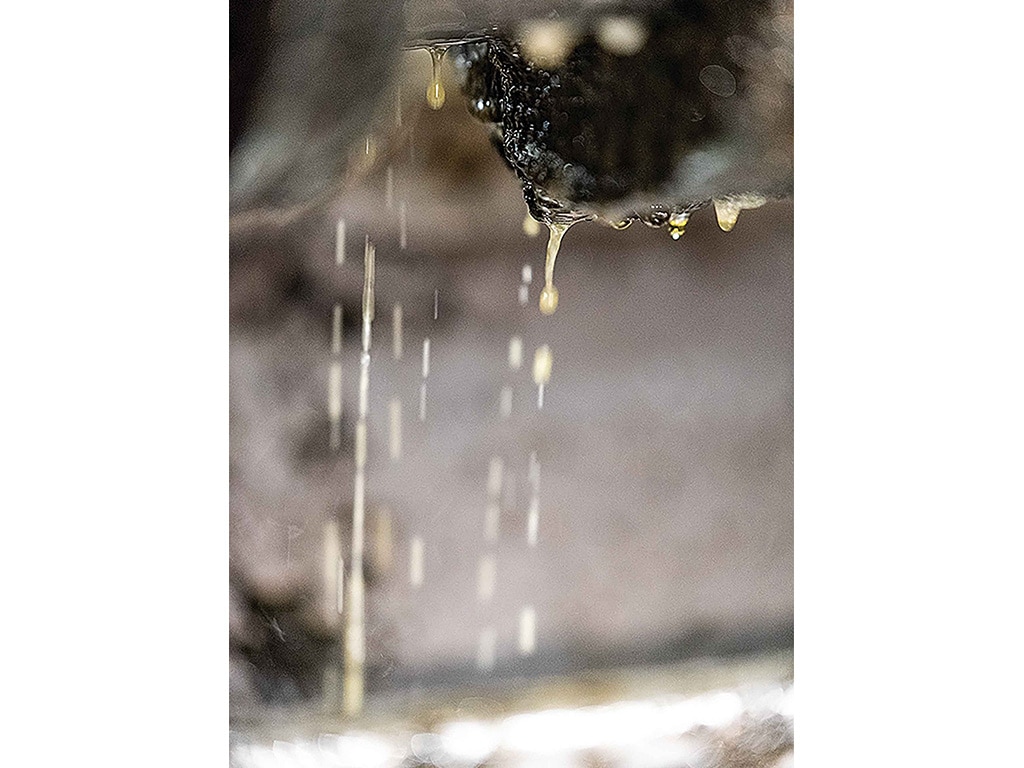

Stormy start. Plan B became Plan A, and they planted a field of sunflowers in 2009 to process for the cattle. The meal would go into the feedlot ration, hulls could be used for bedding, and they would sell the oil on the commodity market.

High-oleic sunflowers seemed like a good addition to their sandy soil rotation because of the crop's deep roots, shorter season length, and different fertilizer and pest management needs than corn, soybeans, and alfalfa.

"Jenni originally said no to sunflower processing, but with the new farm out of the picture, I figured we might as well go ahead with the oil plant," he says.

Tom built a cold-press system to process the sunflower seeds into meal, oil, and hulls conveniently between their bins and feedlot. But when they had 50,000 pounds of food-grade oil pressed and ready for market, the broker backed out of their contract.

Note to other farm couples: Tom does not recommend giving your wife the potential for this big of an 'I told you so' moment.

After frustration gave way to that underlying persistence, the Smudes began bottling the oil and selling directly to consumers at area farmers' markets and distributing through grocery stores. It took a few years and a lot of help from extended family members, but they eventually built up a solid foundation of oil clients while still focusing on their beef herd.

Smudes also sought advice from industry experts including Minnesota's Agricultural Utilization Research Institute (AURI), a 501(c)(3) developed to help grow the state's added-value agricultural sector.

"AURI helped us develop our label and nutrition facts so we could bottle our oil right away. There is no way we would have been able to afford that so early on without their help," Tom explains.

Meanwhile, one can imagine Jenni—who is the accountant of the couple—was looking for ways to balance the risk that was stacking up in 8 oz. glass jars.

Tom's off-farm job had been at his family's John Deere dealership, which also sold a line of grain handling and livestock equipment. As the four-store dealership was merging with a larger, regional dealership, Tom was able to buy out the account and start a new company, Midwest Sales and Construction, in 2011. Today, this business accounts for 35 percent of their overall revenue.

By 2018, the oil was shifting from a byproduct to the main product. They bought a warehouse in their 1,400-person town and added a commercial kitchen to also produce other products using the oil; one that has become quite popular is microwave popcorn. To meet demand, Smudes started contracting local growers to also raise sunflowers.

Above. Initially, Smudes built an on-farm plant to produce meal for the cattle. They put whole sunflower seeds through a cold press to separate the oil from the meal and hulls. Katelyn, Jenni, Mitchell, and Tom Smude pose in their sunflower field at the end of summer (image supplied by Smudes). These fields have become tourist attractions in their own right. The family now offers photo sessions and u-pick times when the sunflowers are at peak bloom. They plant high-oleic varieties and raise Angus cattle.

Clouds begin to clear. Since starting down this diversified, added-value path Tom says the biggest step was starting the new oil plant venture they named Midwest Processing.

"Adding that much and that many people was a challenge. The bigger you get, the more you have to manage. If you are off by 1% in a $200,000 business, you can handle it. When you do millions in revenue, that small percent adds up quickly," says Tom, joking but also matter-of-factly making the correlation to when he started taking blood pressure medication.

Through the stress of managing it all, the added diversification has brought the stability Tom and Jenni were looking for back in 2009.

"Now if one part has a bad year, we can move money and staff around to help the other companies. It's important to not have to lay anyone off," Tom explains with relief in his voice.

Since diversifying and opening up shop in town, they are more focused on offering opportunities and improving their community.

They open the commercial kitchen to other food start-ups and co-pack for smaller brands. And when they expanded the processing business again by adding more presses, they bought a fledgling wood products business housed in the building next door.

"It had been a much bigger manufacturer and no longer needed a building farther from our warehouse. I wanted that building for our new presses so I needed to buy both," Tom explains. Not wanting to put the staff out of their jobs, he and Jenni have helped the manager bring the business back to life.

The cattle will probably always remain at the top of the list for Tom and Jenni, though.

They grew their direct sales during the pandemic's supply chain troubles. With the help of Sprout (a central Minnesota-based non-profit strengthening the local food system), Smudes have worked with more restaurants. Beginning this year through MN Dept. of Ag's Local Food for Schools Cooperative Agreement Program, they will be selling beef to area schools, too.

"We've always wanted to serve local food, and our customers ask for it. Finding USDA- or state-inspected local meat to cook alongside local produce has been a challenge," says Tomas Zimmerman, chef-owner of A.T. The Black & White in Little Falls, Minn. "We were happy when Tom approached us this year. We have been featuring their cuts weekly, and our customers are loving it."

Bright future. After clearing so many hurdles, Tom and Jenni have positioned the business well to bring their children into it.

"Mitchell has been working with the cattle for years between his classes, and really wants to take over that piece," says Tom. "Katelyn has stepped into the oil side since graduating from college and runs our marketing. It is fun to watch the kids grow into what we have built."

Now always thinking about what they can do next, Tom dreams of opening a distillery and restaurant serving smoked meats in their town.

"I think Pierz needs a nice restaurant because you don't always want to go 30 minutes to the bigger towns," says Tom, as a grin starts in the corner of his mouth. New ideas clearly bring him joy. ‡

Read More

AGRICULTURE, SUSTAINABILITY

Rick Clark, Farming Without

Applied fertilizer, nitrogen, lime, insecticides, fungicides, crop insurance and more.

AGRICULTURE, SPECIALTY / NICHE

Reset Farm to Table Dining

The newest way to connect to communities and consumers.