Agile Spider Excavators Over the Edge

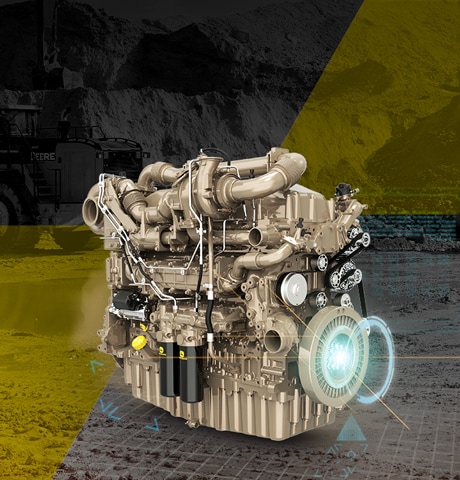

While they are named after the arachnids they resemble, spider (or walking) excavators are also the mountain goats of the equipment world. No matter how challenging the terrain, these agile machines can handle it. With the Euromach R1255 spider excavator, contractors can create a strong niche for their business. This all-terrain earthmover comes with a wide variety of attachments for digging, drilling, or mulching on steep and difficult-to-access terrain. To power the carefully designed excavator, the manufacturer chose a John Deere PowerTech™ PSS 4.5L Stage V engine.

Versatile uses of walking excavators

Euromach Srl in Montichiari, Brescia, Italy, is the daughter company of leading crane manufacturer Cormach. It offers a broad selection of spider excavators tailored to all types of environments: from mountain ranges or swamps to urban settings, ditches, and canals. "Spider excavators are remarkable," says engineer Alfredo Calzoni, technical director of Euromach. "However, the operator and the machine must work in perfect harmony. There are many functions, plus it requires experience to balance and transfer the weight properly for safe and efficient operation."

Euromach aims to address these challenges by designing high-performance models. "Our flexible setup allows us to customize to an extremely high degree. Furthermore, we limit the use of electronics, which adds to the reliability and repairability of our machines," Calzoni continues.

An Italian eye for design innovation

"We strive to create a company culture in which everyone feels encouraged to raise innovative ideas. This is how we can tap into our Italian creative superpower," highlights Calzoni. The new R1255 is a prime example. Designed with the John Deere 4.5L Stage V engine in mind, its combination of power, compactness, and application flexibility offers contractors a profitable return on investment.

The rotating cabin provides the operator full visibility of the working area, while a recently enhanced frame design ensures even better stability. Once the legs are anchored, no complex fixings are needed.

Calzoni expects to sell around 30 of the R1255s per year, mostly in Europe. "The first units are already in the field. Customers love the machine's flexibility and 'can-do' attitude, as well as the fuel efficiency of the engine," Calzoni says. "They need power density, fuel efficiency, and reliability on slopes, and John Deere delivers this, plus expert support worldwide. From our side, we like that the motor wiring is ready for integration and that the engine itself is so simple to integrate."

Euromach has a pioneering spirit

Euromach uses John Deere 4.5L and 6.8L engines throughout its larger spider excavator models, including the R145 Big Foot Forester, which was developed to work in the toughest conditions. This pioneering machine offers enormous power and can be fitted with an optional gear divider allowing the installation of three hydraulic pumps. The R145's John Deere 6.8L Stage III A engine will soon be replaced by a John Deere PowerTech™ Plus Stage V model in the appropriate markets.

Euromach is a long-time customer of Rama Motori S.P.A, the John Deere engine distributor in Italy. "They have consistently given us excellent personal and expert support, from engine choice to 3D drawings, integration, and queries about operation," Calzoni says. "The switch to Stage V technology of course posed some new challenges, and they stood by us all the way. We can't ask more than that."

"With a total of some 200 to 250 spider excavators sold worldwide per year, we're definitely in a niche market. But the demand has grown year over year," Calzoni notes. "Our machines are considered for repairing canals, landslides, and difficult roads in Asia. So we are confident that our spider excavators will climb in demand as well as they climb up a hill."

“We are confident that our spider excavators will climb in demand as well as they climb up a hill.”