The Hay Grinder Just Got Mightier With JD18 Power

Photo courtesy of Jones Manufacturing Company.

Grinding hay — especially tough, stemmy bales — demands a machine with rugged power and unwavering reliability. It's something Jones Manufacturing Company understands well. The company's durable, high-capacity hay grinders are built to tackle the toughest jobs, grinding bales quickly and efficiently to meet the demands of high-volume operations.

But even the strongest machines can benefit from an upgrade, and Jones Manufacturing Company has taken their Mighty Giant hay grinder to a whole new level with the JD18 industrial engine.

Grinding Away

Jones Manufacturing Company, based in Beemer, Nebraska, has been a trusted name in the agricultural industry for more than 70 years. The company manufactures hay and mulch grinders designed with the operator in mind. Renowned for their robust construction and reliability, Mighty Giant grinders are engineered to tackle a wide range of materials.

"Our Mighty Giant grinders can grind just about any kind of fiber or forage. Anything from alfalfa to oat straw to hay — if it can be baled we grind it. But our grinders are also used for other applications like creating cattle feed from various ground-up products," says Rod Giese, owner of Jones Manufacturing Company. "Because our grinders are used to process such a wide variety of materials, we need a rugged solution that can power the machine through the toughest grinds."

Farmers rely on the Mighty Giant as a year-round workhorse. Giese estimates that the average operator clocks anywhere from 1,000 to 1,600 hours annually on their machine. This heavy use puts significant demands on the engine, which needs to withstand constant operation and deliver consistent performance. Recognizing this need, Jones Manufacturing Company sought a power solution that could not only boost the capabilities of their grinders but also enhance fuel efficiency.

"We knew the moment the JD18 was released that it was the power solution Jones Manufacturing needed to take its grinders to the next level," says Justin Stoner, applications engineer at Northstar Power, the John Deere engine distributor based in Ankeny, Iowa.

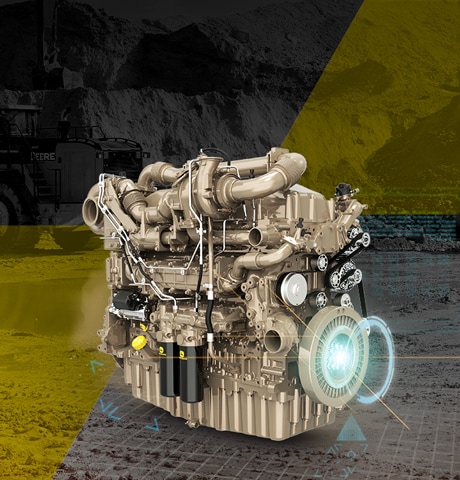

The JD18 industrial engine proved to be the ideal power solution for Jones Manufacturing Company's needs, offering a compelling combination of power, efficiency, and reliability. The 6-cylinder diesel engine has an 18L (1098 cu in) displacement and impressive power output ranging from 700 to 908 hp (522 to 677 kW), so it can drive the Mighty Giant grinders through long hours of operation. Engineered for durability with a robust bedplate design, the JD18 is built to withstand demanding workloads. Furthermore, its advanced technologies optimize fuel consumption.

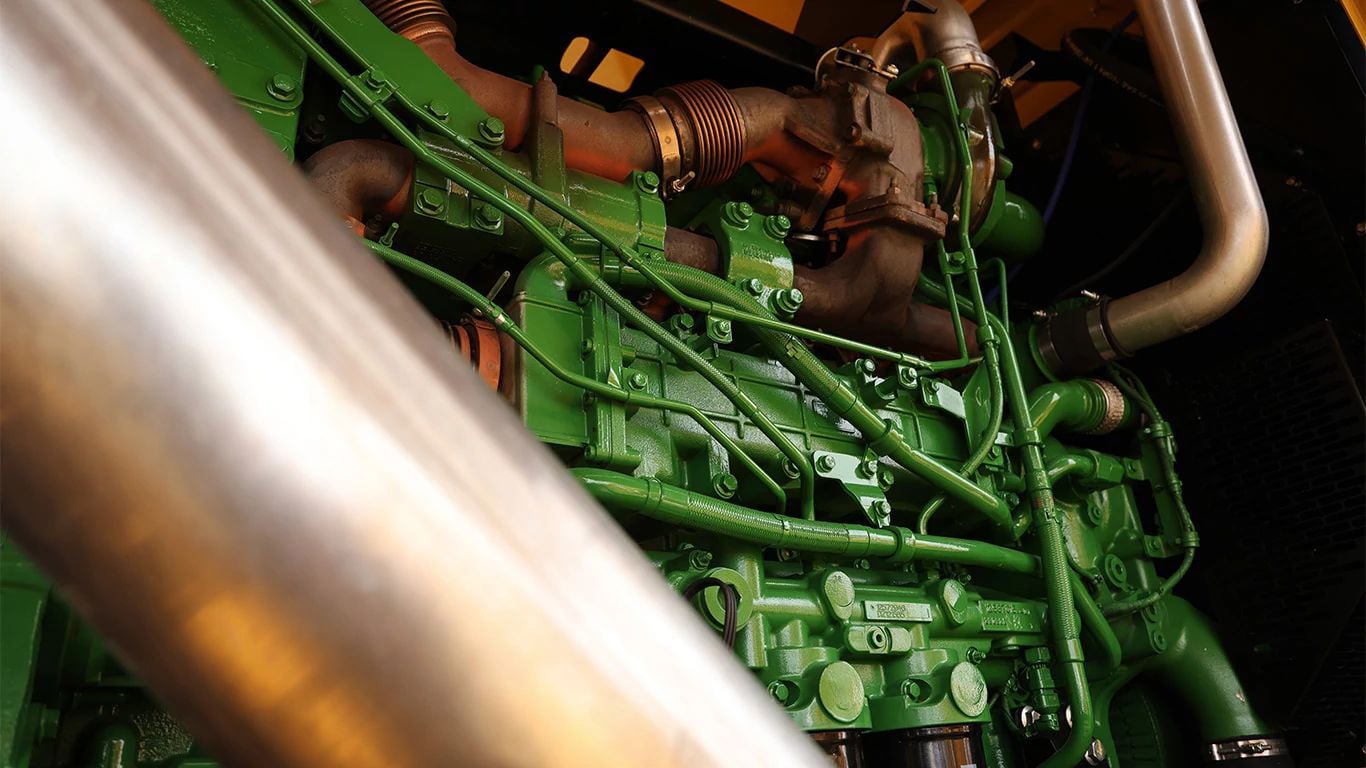

Photo courtesy of Northstar Power

Engineered for High-Volume Operations

Jones Manufacturing Company teamed up with Northstar Power to integrate the powerful JD18 engine into its high-performing hay grinder models 3700, 4100, and 5012. Northstar Power played a crucial role in the design and integration process, ensuring optimal performance and compatibility.

"We worked closely with Jones Manufacturing Company to customize the JD18 power package for their specific needs," says Stoner. "This included overseeing key modifications, such as adding a reverse fan to prevent debris from clogging the cooling system. This helps to optimize uptime."

Jones Manufacturing put the JD18-powered Mighty Giant through rigorous testing, challenging it with the toughest grinding conditions. The testing process focused on key factors: "Consistency, rpms, and raw power were critical. We needed an engine in the 600 to 900 horsepower range with strong low-end torque to maintain optimal tip speed for maximum efficiency. And, of course, it had to be durable enough to withstand the harsh, dust-filled environment of grinding operations," says Giese. "We threw the toughest materials we could find at it. Any machine can grind alfalfa, but ours has a reputation for devouring the really tough stuff. The JD18 impressed us with its speed and efficiency."

Photo courtesy of Jones Manufacturing Company.

JD18 Power Delivers

Customers in the field have echoed Giese's assessment.

"The feedback from our customers who have JD18-powered units in operation has been overwhelmingly positive," says Giese. "They've been particularly impressed with the increased rpms, which translate to greater efficiency and faster processing times. The added torque, which we didn't initially anticipate, has been a welcome bonus, providing even more power to tackle tough grinding jobs."

Jones Manufacturing Company was impressed with the integration expertise and proactive support that Northstar Power offered them throughout the process.

"Northstar's support has been top-notch. It's nice to work with people who are interested in putting a good product together with another good product to create a great product," says Giese. "Between what our machines can do and the power of the JD18, we've been really impressed with the performance."