Breaking New Ground

Located in Envie, Italy, at the foot of the Alps, Pezzolato S.p.A. is on a mission to redefine the wood chipping landscape in direct collaboration with its customers. In response to an English customer's request, the company recently produced a new version of its popular PTH 1200 drum wood chipper powered by a John Deere JD14 engine. Providing more power per liter than previous 13.5L configurations, it is set to enable operators to work faster and more efficiently than ever before.

More engine power, less maintenance

Pezzolato has been a leader in the industrial wood chipper sector for nearly 50 years, competing successfully on a global scale. The company's dedication to performance and customer satisfaction extends far beyond the initial purchase.

Offering a broad range of professional wood chippers, Pezzolato caters to diverse needs: from compact machines for gardeners and greenkeepers to the large and powerful ALL ROAD self-propelled chipper. Alberto Pezzolato, general manager, notes a shift towards more powerful chippers.

"Some of our best-selling models are in the medium to high power range, designed for contractors and large-scale wood chip producers," says Pezzolato. "We provide extensive customization options, including various engines, always ensuring that efficiency, reliability, and ease of maintenance are upheld."

Engineered for heavy-duty chipping operations, the PTH 1200 drum chipper features a robust 660-mm (26 in) diameter drum and a wide infeed table of 1.20 meters (4 ft). Pezzolato's solid drum consistently produces high-quality wood chips of a uniform size, regardless of the type of wood being processed.

Operators can set the functional parameters of the machine and adjust the screening grids according to the type of wood chips they need to produce. The drum's staggered section design evenly distributes the workload, reducing vibrations, noise, and fuel consumption. And now, with the new JD14 industrial engine, customers enjoy increased power and simplified service.

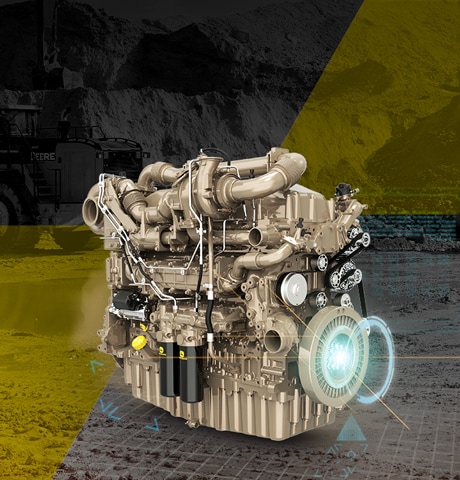

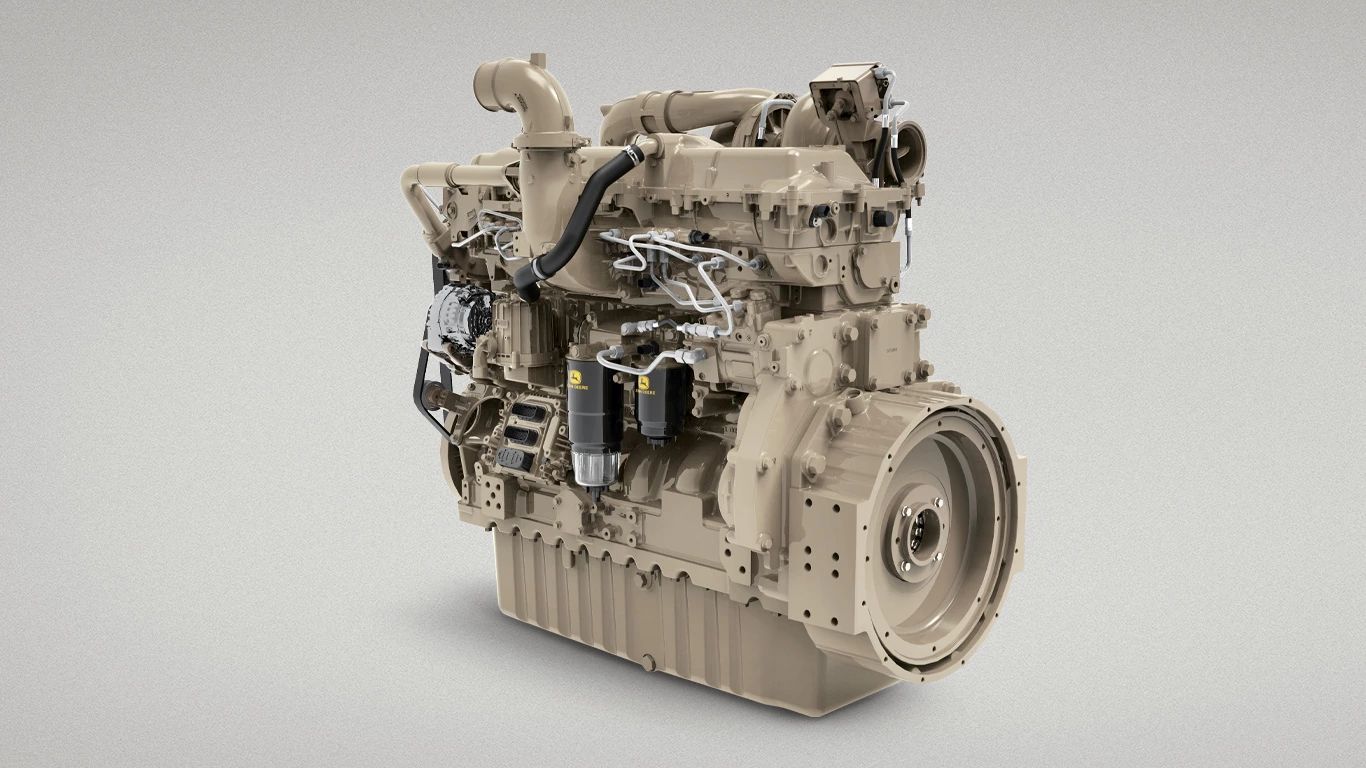

The JD14: Built to perform

The JD14 introduces a new engine architecture that offers easier and more cost-effective maintenance compared to the previous 13.5L model. The 13.6L industrial engine is equipped with self-adjusting hydraulic lash adjusters (HLAs), eliminating the need for manual valve lash adjustments, which are a lengthy service process.

Featuring 391–510 kW (524–684 hp) of continuous, heavy-duty performance, the JD14 provides 14% more power and 11% increased peak torque compared to John Deere engines with a similar displacement. This enhances productivity while reducing noise levels by up to three decibels.

For OEMs, the JD14's reduced footprint takes up less space and offers easier integration compared to the John Deere 13.5L engine. Enrico Menozzi, sales manager at RAMA Motori SpA, John Deere's engine distributor in Italy, highlights this advantage.

"The JD14 is shorter and narrower, fitting into more machines with minimal reconfiguration," says Menozzi. "Moreover, the rear gear trains offer Pezzolato added flexibility for auxiliary power in their chippers."

Pezzolato has a longstanding relationship with RAMA and has been using John Deere 6.8L industrial engines in its smaller PTH 500 and PTH 700 chippers for years, as well as 9.0L engines in the PTH 700 and PTH 900 chippers. RAMA provides Pezzolato with comprehensive engine packages, streamlining installation and ensuring seamless integration with the company's machinery, including the JD14 engine.

"Our priority is always zero downtime, so the engines are rigorously tested after installation to ensure optimal performance from day one,'' says Menozzi.

Pezzolato appreciates the collaborative service experience RAMA provides.

''Over the years, we have established a strong supply and collaborative relationship with RAMA, thanks to their reliable delivery times and technical expertise,'' he says. ''Our design team works in synergy with RAMA on the construction and certification of machines with John Deere engines.''

Future-ready

Pezzolato prioritizes environmental responsibility, which is becoming increasingly important to their customers. The JD14 engine reflects this commitment.

''Overhead cams provide better fuel economy, and the engine also has the flexibility to run on hydrogenated vegetable oil (HVO) and biodiesel up to B20, among other alternative fuels. This is a significant step forward.''

Currently, Pezzolato is integrating the JD14 engine in its maximum power configuration into a PTH 1200/1000 drum chipper. This heralds an exciting future for this forward-thinking, innovative manufacturer.