Powering Steep Forest Harvesters

Joerg Leonhartsberger, CEO of Neuson Forest in Austria, has a lofty goal.

"When people see forest ground with a steep gradient, I want them to think, 'Perfect conditions for a Neuson,'" Leonhartsberger says.

To make his goal a reality, Neuson's tracked harvesters are designed from the ground up for this niche work. The company's latest harvester, the 264HVT model powered by a 9.0L John Deere Stage V engine, is a global all-in-one solution: compact and flexible but delivering greater power density and comfort.

Timber harvesting on steep slopes in remote locations and extreme weather conditions is not for the fainthearted. It takes a "lone ranger" mindset and extremely accurate and reliable equipment to reap the benefits. Neuson's range of machines designed specifically for this demanding work is up to the challenge.

Machines 100% dedicated to steep slope timber harvesting

Neuson's specialized harvesters are nothing like the adapted excavators often used for harvesting. The undercarriage and crawler, for example, are more robust and the undercarriage is slightly larger than the crawler, eliminating tail swing.

The crawler tracks provide optimal grip and low ground pressure while the parallel cranes ensure fast operation with low energy consumption. For maximum uptime, the fold-away cabin gives easy access to all the service points while an integrated toolbox enables the operator to address the most urgent and important issues on-site.

Further supporting the harvesters' reliability are John Deere industrial engines.

"John Deere has experience building forest harvesters, so they understand the unique demands on the engines," Leonhartsberger says.

The 264HVT forest harvester: A single solution for global applications

The latest harvester, the 264HVT, was built to handle anything from second thinning to harvesting individual trunks and final felling.

"Based on customer requests, we particularly wanted to increase the power density and comfort," Leonhartsberger says.

The 264HVT can be fitted with 30-, 33-, or 47.7-foot (9-, 10-, or 14.5-meter) parallel cranes plus a range of harvester heads up to 4,400+ pounds (2,000+ kilograms). Neuson's tried and tested slope compensators guarantee stability.

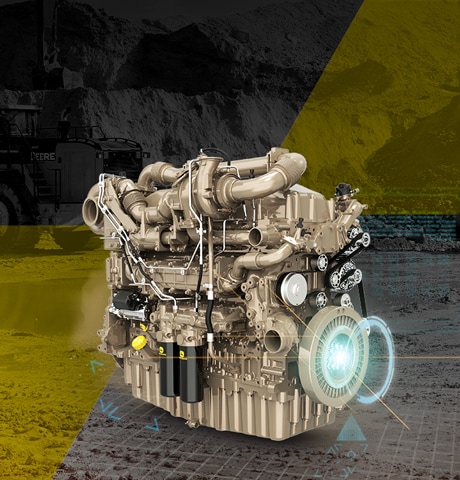

With its John Deere PowerTech™ Stage V 9.0L engine, the 264HVT provides up to 303 hp (226 kW) at a net weight of about 29 tons (26.5 metric tons).

John Deere: Power by forestry peers

Neuson uses John Deere industrial engines throughout its entire range of equipment, from a 4.5L engine in the smaller 103 and 104HVT harvesters to a 6.8L engine in the medium-sized 204 harvester. The engines supply propulsion power and drive the hydraulic pumps.

John Deere has been the chosen engine brand for Neuson since its beginnings in 2010.

"Staying loyal to one brand throughout our range sends a powerful message to our customers that we value consistency," Leonhartsberger says. "Plus, our support network can build their understanding of the technology to better serve our customers."

Rama support

In 2022 Rama Motori S.p.A., the John Deere distributor for Italy and the Balkans, took over distributorship in Austria and Switzerland. Leonhartsberger visited them in March.

"I was very impressed with their operations and mindset. They're a mature John Deere distributor with a lot of expertise and a healthy stock of engines and spare parts," he says. "Our engineers are already brainstorming with Rama's on the smaller harvester. Tim Koehler from Rama Austria is our main contact. We've known him for years and he knows our business like no one else."

Growing sustainably

Leonhartsberger sees great opportunities for growth in Europe, North America, and Asia.

"We're adding new dealers to our global network every year and last year we moved into a new plant," Leonhartsberger says. "We're currently producing around 30 units per year but want to ramp this up to 50. And next year we will increase the boom and head options for the global market."

As for Neuson's product line, Leonhartsberger says their team is continuing to look for ways to grow their specialized equipment offerings.

"We're a small team and prefer to keep our range like our machines: compact. That said, we're working on a smaller and a larger harvester," he says. "It's good to know John Deere's range offers us the flexibility to meet future demands. The 9.0L engine has sufficient torque for a possible larger harvester while the 4.5L will be a perfect match for a smaller unit we are working on."