Powering Trench Burners

The McPherson family got a unique start to their business venture when they saw a local need for peanut-drying equipment. They started their operation with just a 12- by 18-meter (40- by 60-foot) shop equipped with a few welders and a metal shear — working with local peanut-drying operations to provide the necessary equipment.

After a few years, they had the knowledge and expertise to modify existing equipment designs, switch their business model, and begin manufacturing refractory-lined pit burners and trench burners powered by John Deere engines. Three generations later, McPherson Systems, Inc., of Tifton, Georgia, has been burning through the competition ever since.

Zach McPherson, engineer at McPherson Systems, Inc., began his journey with the family business at just 12 years old; working his way through the ranks assembling machines and even stepping into fabrication before he left for Georgia Southern University.

"I graduated with a mechanical engineering degree and then started working for Flint Power, a John Deere Power Systems distributor, as an application engineer," says McPherson. "And that's actually how McPherson Systems got into using John Deere engines."

Engineer brings insider expertise to trench burner business

Working at Flint Power, McPherson had the opportunity to change his perspective as an agent representative and application engineer for his family's company.

"McPherson [Systems] bought one or two John Deere engines while I was at Flint, and I actually did the application testing on the first unit," he says. "It was nice to go back and oversee that process and be a major player on both sides."

After working with Flint Power for three years, he changed roles again — this time making his way back home to McPherson Systems, Inc.

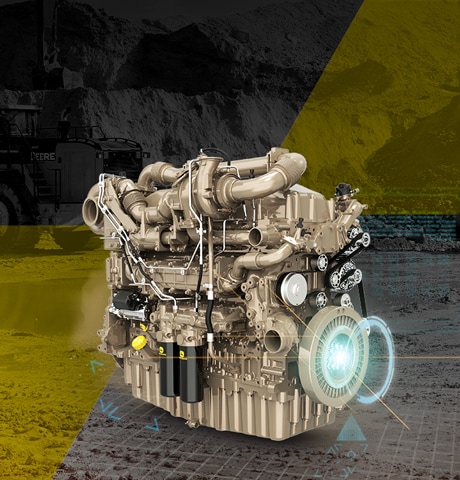

"We hit the ground running with the John Deere PowerTech™ EWX 4.5L engine at 74 hp (55 kW). It just fit the bill perfectly," details McPherson. "We didn't have any complaints. We have several of them that have put in several thousand hours in an incredibly harsh environment."

That environment includes temperatures as hot as 2500 degrees Fahrenheit and surrounding air filled with smoke, ash, and soot.

McPherson Systems benefits from close integration

When McPherson returned to his family company, he brought with him a developed skillset and deep knowledge of John Deere engines. This enhanced the dynamic of a typical distributor-customer relationship.

"It really gave us an advantage. We don't have to go back and forth too terribly much as far as what engine we need, what size, or what particular requirements we have," says McPherson. "If we have an issue, we know who to talk to about it, and we've built a good-standing relationship. It takes me about an hour and half to get out of there, talking to and catching up with everybody."

Right out of the gate, McPherson knew exactly what he needed from Flint Power and how to better integrate the engines.

He knew he and his team didn't have to worry about the already hardened John Deere engine, even in the harshest of applications. Taking into account special requirements upfront, like having a rigid frame to withstand high amounts of vibration, has made a positive change in the longevity of the McPherson's burners.

Trench and pit burners built to last

McPherson Systems, Inc., prides itself on building "the heaviest machine possible," as McPherson describes.

With a heavier, more durable machine, you can achieve a hotter burn — and the hotter the burn, the cleaner the burn. This means the machine is working as efficiently as possible. In fact, many of McPherson's customers will tell anyone looking for a burner, "If it's not a signature McPherson machine, don't hook it to your truck."

After years of refining equipment designs and working with (and briefly for) a John Deere distributor, Zach McPherson has continued the family legacy of McPherson Systems, Inc. Their strong, durable, and innovative equipment has met its match in a strong, durable, and reliable engine that will continue to empower them to provide a safe, clean way to dispose of wood waste. Using a trench or pit burner is more efficient and compliant with state and local laws than open burning.

We hit the ground running with the John Deere PowerTech™ EWX 4.5L engine at 74 hp (55 kW). It just fit the bill perfectly. We didn't have any complaints.