Pumping up the Power for Oilfield Water Transfer

Gainesville, Texas is home to a family-owned and -operated company that is steadily supporting the oilfield industry with its innovative fracturing, blending, cementing, and pumping units for the oil and gas industry, along with a full-service business model. The team at ORTEQ Energy Technologies (ORTEQ), a premier designer and manufacturer of custom oilfield equipment, isn't just passionate about the oil and gas industry — they understand it on a fundamental level.

This deep understanding fuels ORTEQ's commitment to exceeding expectations and to ensuring that its oilfield equipment is built for peak performance and reliability; a characteristic that the entire oilfield industry hinges on. Often grinding for 20 to 24 hours a day, oilfield operations are in pretty much perpetual motion to meet increasingly demanding quotas. ORTEQ's reliable pump applications require a matching source of reliable power. That's why they are run by John Deere industrial engines.

Pump up the volume

The unsung hero of these bustling oil fields is the constantly humming centrifugal water pump. Pumping units are the backbone of the hydraulic stimulation process — commonly referred to as fracking. Hydraulic stimulation uses water to extract oil and gas deposits that lie deep beneath the surface, trapped within rock formations. Centrifugal pumps transport high volumes of water to the well sites that will then be used in the mixture that is injected into the rock formation to create fractures.

These allow the trapped oil and gas to flow more easily to the wellbore where it can be collected. ORTEQ's pumps move up to 10,000 gallons of water per minute across vast distances to well sites. The water used in fracking is often sourced from miles away, and ORTEQ's pumps ensure a steady and reliable flow of water to the operation.

ORTEQ also has the experience and skill necessary to customize these units for other markets, including municipal and industrial applications that are looking for maximum pumping power.

New engine, same reliable performance

The heavy-duty pump applications require a power source that can withstand continuous use in harsh environments, ranging from scorching deserts to freezing fields. For years, ORTEQ has turned to its John Deere engine distributor — engines, inc. — for the power generation needed for its water pump units. As the authorized John Deere engine distributor for the southern United States, including Texas, New Mexico, Arkansas, Louisiana, and Mississippi, engines, inc., is proud to be in the heart of America's oil country serving customers like ORTEQ. From meeting delivery schedules to providing exceptional service and parts availability, the power application expert has helped make sure ORTEQ has the resources it needs to succeed.

"engines, inc., has been a really good partner of ours," says Cole Ortowski, co-owner of ORTEQ. "They've done what we've asked. They support us anytime that we need it."

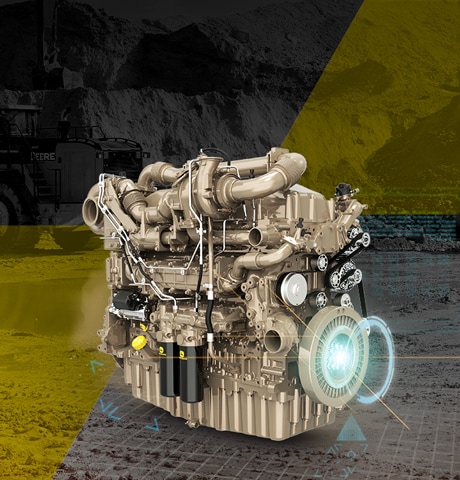

The two companies recently worked together to revamp ORTEQ's centrifugal pump product with the JD14 industrial engine. The existing pump was powered by a 13.5L engine, but the manufacturer was ready to upgrade their power to the latest and greatest engine from John Deere. This powerful and efficient solution meets stringent EPA Final Tier 4/EU Stage V emission standards while delivering the reliable performance ORTEQ and its customers have come to expect from John Deere.

A seamless engine swap

Bracken Baker, engineering manager at engines, inc., collaborated with the ORTEQ design team in selecting the JD14 industrial engine to meet the company's demanding water transfer needs.

"The JD14 was a natural fit for ORTEQ's water transfer application because it maintained a lot of the same customer connection points as the previous model that leveraged the 13.5L engine." says Baker. "This simplified the transition for ORTEQ and made the JD14 a drop-in replacement for their existing pump designs."

engines, inc., was able to streamline the repower process by keeping the same crank center line and maintaining the same footprint as the 13.5L-powered pump. This, in turn, allowed ORTEQ to keep its same skid mounting pattern and avoid unnecessary and costly equipment spec changes. engines, inc., was also able to simplify the water pump's aftertreatment with the single-canister design of the JD14.

Beyond the technical advantages and seamless integration, the JD14 engine has proven to be a powerhouse ORTEQ and its customers can rely on.

"Our customers have been extremely pleased with the JD14 units," says Ortowski. AQUACORE Rental Company — a leading provider of water solutions and rental equipment for the oil, gas, and construction markets — purchased 50 water transfer systems powered by JD14 engines and has 15 more on the way. ORTEQ is confident that the JD14 will be a top engine of choice for its oil and gas customers.

Looking ahead, ORTEQ is committed to developing innovative and reliable solutions for the oil and gas industry. Their long-term relationship with engines, inc., and John Deere gives them the power to meet the ever-growing demands of this dynamic industry.