“It used to take us 4 weeks to drill, and now we are getting it done in about 3 weeks. The only change that we’ve made is adding Turn Automation. That’s been a huge factor for us, and a huge time savings.” – Western Oregon Grass Seed Grower

You are human. Accurate and consistent turns are difficult to manually repeat throughout a long workday, especially when the dust kicks up and the sun goes down.

You are also a farmer. We understand that you are always striving to do your job better.

Easily complete end-of-pass turns no matter your in-cab experience

Easily complete end-of-pass turns no matter your in-cab experience

Whether you are planting, seeding, or harvesting, as the operator, you must be on top of your game all day, every day; performing various tasks at the right time and in the right place to maximize your inputs. As the hours pass and fatigue sets in, machine maneuvers and performance can become inconsistent and lead to rework or mistakes you must live with the rest of the season.

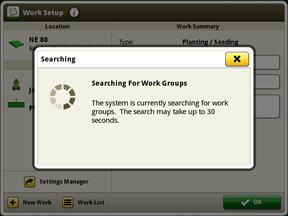

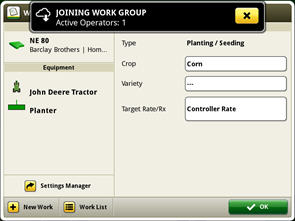

AutoTrac™ Turn Automation (ATTA) addresses these challenges head-on, by planning and automating precise, repeatable, and efficient turns at the end of each pass. Set up the display to fit your operation, and let ATTA go to work for you.

ATTA offers numerous benefits to the operator:

- The power to focus on the job at hand, making necessary adjustments and better agronomic decisions on the go

- The ability to watch the tractor/implement or combine/header more closely, allowing for proactive adjustments instead of reactive fixes

- The capacity to more diligently watch for damaging obstacles such as rocks, washouts, or holes throughout the field

- The potential to increase productivity through faster, more efficient, and smoother turns in the field’s headland, no matter who is in the operator’s seat

- BONUS: ATTA for tractors incorporates end-of-row functionality, like speed and implement control, that takes this already beneficial feature to the next level

- Operators can enjoy more hands-free time through automating a high repetition task, resulting in reduced stress levels