Efficiency in Motion

Photography courtesy of Wiesner Metal Fab.

Tucked away in the corner of the United States Pacific Northwest region lies Willamette Valley — a picturesque stretch of land surrounded by mountain range vistas and threaded with rivers and waterways. This temperate valley is home to prime hazelnut-growing conditions and equipment experts Wiesner Metal Fab.

A fabrication and repair company based in Brooks, Oregon, Wiesner Metal Fab specializes in agricultural, nursery, and hazelnut equipment. Established in 1988, the company handles a full range of fabrication needs, from small repairs to the design and building of nut processing facilities from the ground up. Wiesner Metal Fab also designs equipment for customer-specific applications. One of the latest innovations to come from the company is a self-propelled hazelnut harvester.

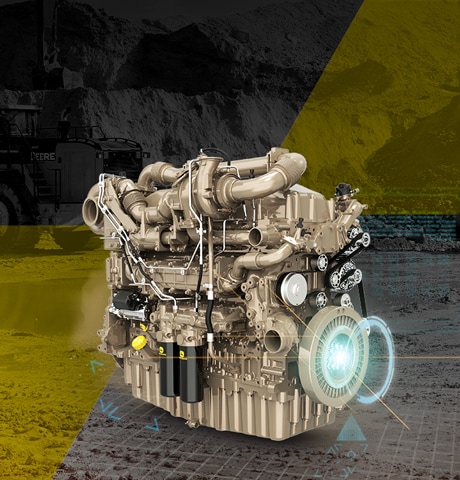

When looking for a solution to power this machine, Wiesner Metal Fab needed a rugged engine that could withstand the dusty environment of an orchard and provide the power needed to successfully harvest nuts in one pass. Cascade Engine Center, the John Deere engine distributor for the Pacific Northwest, helped develop an integration package for Wiesner Metal Fab using a John Deere 4.5L Final Tier 4 industrial engine, which offers 155 hp (114 kW) of power.

Leveraging its decades of engine application expertise, Cascade Engine Center designed a custom power package for the harvester that integrated a John Deere 4.5L industrial engine with a Funk 59000 Four Plate Hydraulic Pump Drive.

Powering Customization and Innovation

In a narrow window of time during September and October, hazelnut farmers are hard at work in their orchards harvesting nuts that have fallen to the ground. With its self-propelled solution, Wiesner Metal Fab is bringing efficiency and precision to hazelnut orchards.

"Our machine helps to simplify a farmer's harvesting operation. Previously, harvesting required an operator for the sweeper, a tractor driver, and a chase vehicle for retrieving the harvested nuts. With our new self-propelled machine, hazelnut farmers can streamline their equipment needs and harvest more efficiently," said Mark Wiesner, owner of Wiesner Metal Fab. "The self-propelled solution allows farmers to harvest with just one pass through the orchard, bringing significant time savings for a farmer's operation."

Cascade Engine Center has been working with Wiesner Metal Fab since 2016. Wiesner Metal Fab was looking for a higher horsepower engine for the next iteration of the harvester that could also operate a Funk Hydraulic Pump Drive. Leveraging its decades of engine application expertise, Cascade Engine Center designed a custom power package for the harvester that integrated a John Deere 4.5L industrial engine with a Funk 59000 Four Plate Hydraulic Pump Drive. This package offered easy integration and the powerful performance the customer was looking for. Cascade Engine Center knew the John Deere 4.5L engine was up for the challenge and could reliably keep the machine and added hydraulic motors running during a short, busy harvest season.

Cascade Engine Center also helped to design a custom wiring harness for the self-propelled machine. The 15-foot harness connects all of the controls from the cab at the front of the machine to the engine that is located at the back of the machine — making it simple and easy to manage the various electronic components of the equipment.

Photography courtesy of Wiesner Metal Fab.