Pumped With Power

In an industry where uptime is everything, Bazooka Farmstar is always looking for ways to provide its customers with a better flow for their bottom line.

A liquid manure equipment manufacturer with nearly 50 years of experience as one of the industry's leaders, Bazooka Farmstar works to deliver the best liquid manure management solutions for its customers. The company serves customers in the U.S. and Canada. While its primary business is manure equipment, Bazooka Farmstar also manufactures oil and gas and agricultural equipment.

"Over the years, the company's main focus has evolved from just manure equipment for hog confinement and application into the field into other services and industries," says Phil Minino, director of engineering and product development for Bazooka Farmstar. "We've grown and gotten into other markets like the dairy market where they have big lagoons for manure storage."

In the business of liquid manure management

Based in Washington, Iowa, Bazooka Farmstar is located in "the heart of hog production," says Minino. Manure management is an integral part of the industry.

The clock is always ticking for liquid manure applicators due to the limited timeframe in which liquid manure can be applied. The main season is in the fall, from right after harvest until the ground freezes. There is also a narrow window of opportunity to apply manure in the spring after the ground thaws and before crops are planted.

With such a short application window, uptime is vital to a manure applicator's success. And just as important is having a powerful manure pumping unit that can deliver a fast and efficient flow to ensure that no time is wasted in such a critical operation period. The power of liquid manure pump units is measured in gallons per minute, Minino explains.

"Earlier models of our equipment were pumping between 1,500 to 2,000 gallons per minute. The philosophy was slow and steady wins the race," Minino says. "But then everybody started understanding that with bigger hoses and higher horsepower engines they can get these jobs done a lot quicker and still do it safely."

When it comes to horsepower and finding the right solution to match original equipment manufacturer (OEM) needs, John Deere engine distributor Northstar Power LLC is an expert.

With the clean-sheet design of the JD14 and focus on a more compact, lighter footprint, this engine offers a competitive advantage our OEMs are looking for.

Customer Service the 'Iowa Way'

Iowa-based Northstar Power and Bazooka Farmstar began working together in 2014 after the OEM reached out about John Deere 9.0L and 13.5L Tier 3 engines. Northstar Power helped to create engine packages that would provide Bazooka Farmstar with the horsepower it needed.

"We pretty much always run the highest horsepower each engine package can have. We also make sure our cooling packages are sufficient for what we're trying to run and that they can handle summer conditions, especially with the heat some of our clients can get in the south," Minino says. "Northstar Power also really helped us to navigate the Final Tier 4 changeover, which was a huge adjustment for manufacturers."

Bazooka Farmstar worked closely with Northstar Power to redesign its manure pump units to fit with the engine package's footprint. In addition to mentioning engineering and design support, Minino also highlighted Northstar Power's commitment to service and the benefit of how close the distributor is — being based in Ankeny, Iowa.

"If we do have problems, they get in the car and come in person to help us troubleshoot. That's the 'Iowa Way' I guess you could say," Minino says. "John Deere engines come with great power and reliability and are backed by a huge dealer service network. With the limited manure application season, applicators can't have downtime, so getting back up and running if an issue does occur is vital. Having access to the vast John Deere service network is a great benefit of using John Deere engines in these machines."

Bringing On the JD14 Industrial Engine

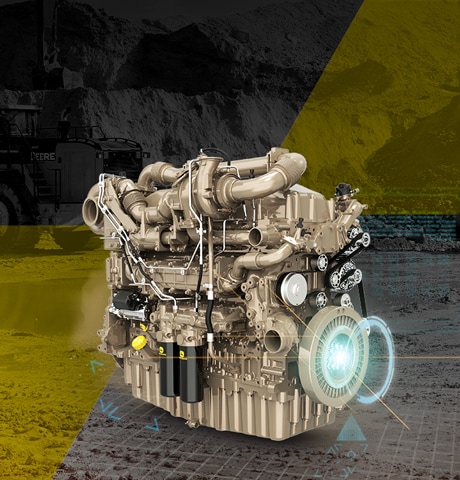

When John Deere introduced its Next Generation engine (NGE) platform, Bazooka Farmstar was interested in what this new set of powerful engines could do. The NGE lineup leverages a new engine architecture that features the best of John Deere technologies to deliver new levels of reliability, durability, flexibility, and serviceability for a wide array of heavy-duty applications.

Intrigued by the power density and serviceability potential of the JD14, Bazooka began exploring the possibility of powering the company's new Outlaw Boom Trailer.

"With the clean-sheet design of the JD14 and focus on a more compact, lighter footprint, this engine offers a competitive advantage our OEMs are looking for," says Brian Mezera, account manager for Northstar Power.

The JD14 offers 391-510 kW (525-684 hp) in power. With the JD14 onboard, the Outlaw is able to pump 4,000 gallons per minute. The engine also has the capacity for additional pumps with an integrated power take-off and multiple aux drive connections.

"We took the opportunity with the release of the JD14 because with this little bit of extra horsepower that we're getting, we're able to pump more gallons in a more efficient way than we've done in the past," Minino says. "It's a great sweet spot because we trade off horsepower given to the main pump off the flywheel versus the auxiliary hydrostatic pump on the rear PTO, which runs a submersible pump and force-feeds manure into the main pump. One no longer limits the other and we can run the main pump to its full potential without having to jump into the next larger engine displacement, which comes with added cost and size."

The Outlaw Boom Trailer recently launched and made its debut at the 2023 World Pork Expo. Minino says that Bazooka Farmstar already has orders lined up for JD14-powered units. The company has big plans to keep pushing the power when it comes to its nutrient pumps. It has a JD18 (522– 677 kW (700 — 908 hp)) ordered and will be ready to hit the field for testing it later this summer in one of its Outlaw units.

"We're happy with what we've been able to do with the JD14 and look forward to seeing what kind of flow we can get with the JD18 once it's delivered," Minino says. "It will go on a similar setup to the JD14 units with a bigger pump and bigger hydrostat that runs the submersible off the rear PTO. We're hoping to get 5,000 gallons per minute."